| Place of Origin: | China |

| Brand Name: | zealchon |

| Certification: | ISO |

| Model Number: | ZCQ75 |

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | $15000 |

| Packaging Details: | wooden box |

| Delivery Time: | 7days |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 100sets/month |

| ZCQ75: | 290 A | Max. Speed: | 1450 R/min |

|---|---|---|---|

| Max. Amplitude: | 18.9 Mm | After-sales Ser: | Engineers Available To Service |

Vibro replacement is a ground improvement technique that constructs dense aggregate columns (stone columns) by means of a crane-suspended downhole vibrator, to reinforce all soils and densify granular soils. Vibro replacement stone columns are constructed with either the wet top feed process, or the dry bottom feed process.

In the wet top feed process, the vibrator penetrates to the design depth by means of the vibrator’s weight and vibrations, as well as water jets located in the vibrator’s tip. The stone (crushed stone or recycled concrete) is then introduced at the ground surface to the annular space around the vibrator created by the jetting water. The stone falls through the annular space to the vibrator tip, and fills the void created as the vibrator is lifted several feet. The vibrator is lowered, densifying and displacing the underlying stone. The vibro replacement process is repeated until a dense stone column is constructed to the ground surface.

The dry bottom feed process is similar except that no water jets are used and the stone is fed to the vibrator tip through a feed pipe attached to the vibrator. Predrilling of dense strata at the column location may be required for the vibrator to penetrate to the design depth. Both methods of construction create a high modulus stone column that reinforces the treatment zone and densifies surrounding granular soils.

Vibro replacement stone columns have been used to increase bearing capacity, and decrease settlement and mitigate liquefaction potential for all types of planned structures including buildings, embankments, dams, tanks and towers.

Vibro replacement rigs can be fully instrumented with an on-board computer to monitor specific parameters. Monitoring these parameters allows the operator to correct any deviations in real-time during the construction process to keep the stone column within project specifications. Data from the Data Acquisition (DAQ) system such as amperage and lift rate are recorded and displayed in real-time alongside specified target values on an in-cab monitor.

![]()

![]()

![]()

![]()

Mixed and fine-grain soils frequently have an insufficient bearing capacity and stiffness. Should the fine grain share be around 5% higher, an adequate self-compaction is no longer to be expected. This is where the vibro replacement compacting comes into question as an improvement. This process is also suitable for the improvement of coarse-grain backfills comprising rubble, slag or overburden.

A special area of application are vibro drain columns. Flotation is dispensed with hereby. The column then merely acts as a drain.

In most cases, a bottom feed vibrator is used, with which a coarse-grain fill material is discharged at the tip of the vibrator with compressed air support. The vibrocats with a leader that have been designed by Keller provide an additional pull-down pressure to be applied when the vibrator is being lowered and is compacting.

In vibro replacement compacting, the work is carried out in alternate steps. The gravel or crushed stones that are discharged from the vibrator hub are compacted and displaced into the soil at the side. This results in the formation of replacement columns that bear the loads in connection with the soil. The creation parameters are digitally recorded in the device.

ZCQ series variable frequency electric drive Vibroflot technical parameters

| specification | ZCQ45 | ZCQ55 | ZCQ75 | ZCQ100 | ZCQ130 | ||

| Vibro Motor |

rated power | kw | 45 | 55 | 75 | 100 | 130 |

| Rotating speed | r/mim | 1450 (1950) | 1450 (1950) | 1450 (1950) | 1450 (1950) | 1450 (1950) | |

| Current Rating | A | 86 | 110 | 150 | 196 | 256 | |

| Vibration move machine body |

Vibration frequency | HZ | 24 | 24 | 24 | 24 | 24 |

| Moment | N.m | 47 | 56 | 69 | 78 | 88 | |

| Exciting force | kN | 110-200 | 130-235 | 180-325 | 190-350 | 210-380 | |

| Empty vibration amplitude | mm | ≥18 | ≥16 | ≥15 | ≥15 | ≥16 | |

| Empty LO current | A | ≤35 | ≤40 | ≤50 | ≤60 | ≤70 | |

| The outer diameter of the body | mm | 351 | 377 | 426 | 426 | 426 | |

| Body length | mm | ≤2230 | ≤2465 | ≤2600 | ≤2750 | ≤2860 | |

| The total mass | kg | 1000 | 1350 | 1800 | 1950 | 2200 | |

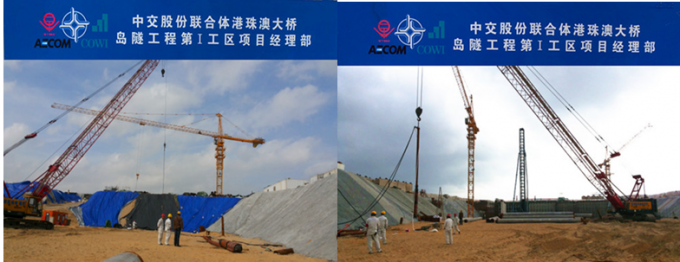

Previous project pictures

China Sinopec Hainan commercial crude oil reserve base project

HZMB Island tunnel project

China Sinopec Caofeidian crude oil commercial reserve base library project

International market

Companies based in China, the world. Actively explore the international market, international sales companies are mainly concentrated in Africa, the Middle East and Asian countries, including: Benin, Sri Lanka, Indonesia, Malaysia, Algeria and other countries, and high customer credibility and visibility.

1, Chinese Embassy in Benin project equipment procurement negotiations

Indonesia Port and foundation construction of offshore Vibro